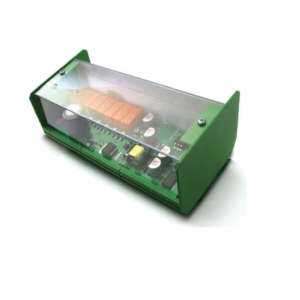

Description

- Engine Auto start and Stop on multiple triggers via float switches, Pressure, Flow Switch, SAT/GSM modems, PLCs and RTU’s.

- Bi-directional remote telemetry connection to a PLC and SCADA networks and to a website via Satellite or GSM modem.

- Bright graphical display showing all engine/equipment data and warning/faults.

- Complete asset protection on all sensors with built in ‘Failsafe’ protection. Includes low radiator coolant level detection.

- Connects to various analogue sensors, ie: 4-20mA pressure or flow sensors, including resistive sensors.

- Multiple sensor readout, with built in separate adjustable bypass timers and slush timers.

- Robust IP66 control module in a powder coated enclosure with tempered see through glass. Will not yellow in exposed sunlight.

- Automatic engine speed control to fixed speed, via CANBUS J1939 or MODBUS. (Optional extra, Pulse Width Modulation via electronic actuator on mechanical engine also available). Can also be controlled remotely

- Save on fuel, running and maintenance costs. Fuel Level monitoring.

- Built in warmup and cooldown timers.

- Programmable 100hour run timer.

- One panel to suit mechanical engines or electronic CANBUS J1939 engines.

- Tier 4 emissions ready.

- In built data logging on all equipment faults.

- Engine Running output.

- Easy to set up and program. Will permit future software upgrades via a computer.